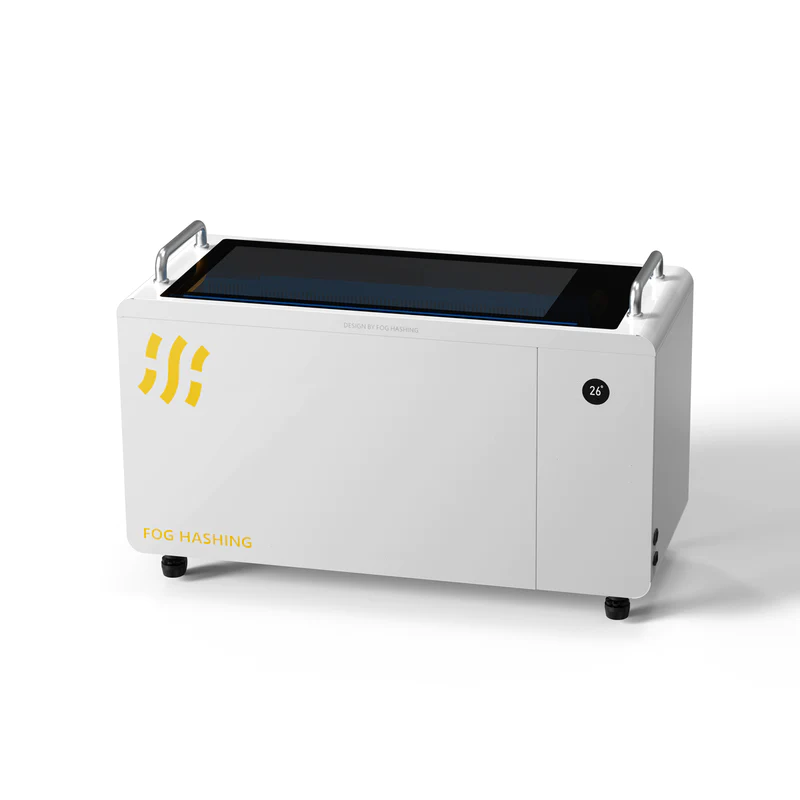

Compact and Efficient Cooling Solution: C6 Tank

The C6 Tank offers a compact and efficient solution for cooling systems, with outer dimensions measuring 1185(L) x 530(W) x 760(H) mm and a gross weight of 110 kg. Designed for single-loop operation, it can handle a substantial coolant volume of 200L, ensuring effective heat dissipation. With a maximum power usage ranging from 800W to 1100W, this tank operates quietly at a noise level of 45dB(A) at 10 meters, making it suitable for various environments. Its electrical interface, featuring a single-phase input voltage of 200-240V at 50/60Hz and a C14 connection, facilitates seamless integration into existing systems. Additionally, the C6 Tank supports the capacity of 6 x S19/S21 or 8 x M50/M60 miners, making it versatile for different mining setups.

Reliable Power Distribution: PDU Configuration

The PDU configuration of the C6 Tank ensures reliable power distribution, catering to the diverse needs of mining operations. With options for single-phase 220V 125A 6C19 or three-phase 380V 63A 6C19, it provides flexibility in power management. This setup allows for efficient utilization of resources while maintaining stability and safety within the mining infrastructure. By offering multiple options for electrical connectivity, the C6 Tank’s PDU configuration enhances scalability and adaptability, enabling miners to optimize their operations according to their specific requirements.

Supreme for Small Scale Mining

Extremely minimalist design, and effortless deployment.

Safe, reliable, and stable design for coolant circulation.

Support 6 mining rigs inside.

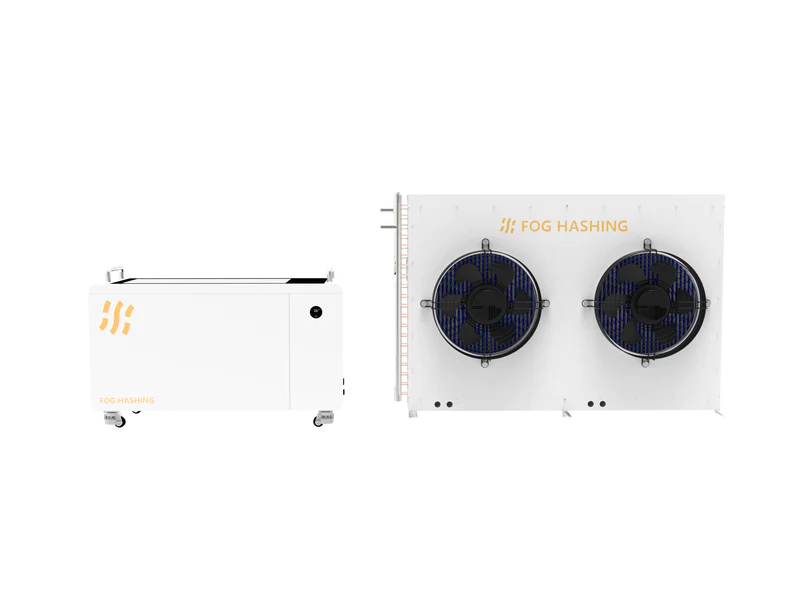

Advance Cooling Capabilities

Exceptional cooling performance:

21kW@38° C, 24kW@35° C, 28kW@33° C.

Optional water mist enhances heat dissipation and maintains efficiency even at high temperatures of 42° C.

Intelligent Speed Adaptation and Energy-Saving

Equipped with built-in EC motors that automatically adjust fan speed in response to changes in ambient

temperature.

Provide continuous operation with optimum energy efficiency and a minimum of noise.

Automatic Adjustment and Status Monitoring

loT sensors can help monitor the running status.

Automatically controlling the inlet liquid temperature is achievable through PID algorithm adjustment.